What is the firesleeve tape?

Firesleeve Tape – Professional-Grade Thermal Protection Solutions by BSTFLEX

BSTFLEX offers two premium types of Firesleeve Tape, designed to enhance thermal protection, extend service life, and simplify installation in demanding environments. Whether you're sealing the ends of a Firesleeve installation or wrapping complex, high-temperature systems, our Firesleeve Tapes provide durable, reliable solutions tailored for industrial performance.

1. End Seal Tape – Pure Silicone Rubber Construction

Our End Seal Tape is manufactured from high-grade, pure silicone rubber and is engineered specifically for sealing the ends of installed Firesleeve. This helps to prevent the ingress of water, dirt, sand, dust, and other contaminants that can compromise thermal performance and hose integrity.

-

Self-Amalgamating Design: Unlike traditional tapes, this tape mechanically bonds to itself without any adhesive, forming a seamless, durable layer. The absence of glue means there’s no sticky residue and no compromise on thermal resistance.

-

High Temperature Performance: Designed to withstand extreme temperatures without degrading or losing strength.

-

Clean and Simple Application: Easy to install and remove, ensuring clean, professional finishes.

Typical Applications:

Transportation, Railroad, Oil & Gas, Industrial Machinery, Mining Equipment, Automotive Systems, Forestry, Military, Aerospace, Firefighting Gear, Rally Cars, and Smelters.

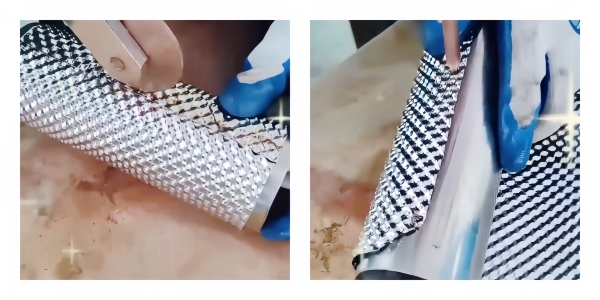

2. Firesleeve Tape – Silicone-Coated Fiberglass Construction

The Firesleeve Tape is a versatile, wrap-around thermal barrier composed of a durable fiberglass base with a high-performance silicone rubber coating. It delivers the same trusted protection as traditional Firesleeve but in a flexible, tape format.

-

Flexible Installation: Ideal for wrapping large-diameter components, irregular geometries, high-temperature piping, and foundry equipment.

-

Flame and Splash Resistance: Offers exceptional resistance to molten metal splash, radiant heat, and direct flame exposure.

-

Extended Equipment Lifespan: Helps prevent costly hose failures, reduces downtime, and protects workers from burns and equipment from heat-related damage.

Ideal For:

Foundry systems, engine compartments, heat-intensive piping, maintenance wraps, and retrofit applications across industrial, automotive, and aerospace sectors.

Choose BSTFLEX Firesleeve Tape

Engineered for durability, designed for convenience—BSTFLEX Firesleeve Tapes are your go-to solutions for reliable thermal protection in the most challenging environments.