AC cooling fan introduction - Chungfo Electronic

AC cooling fan introduction - Chungfo Electronic

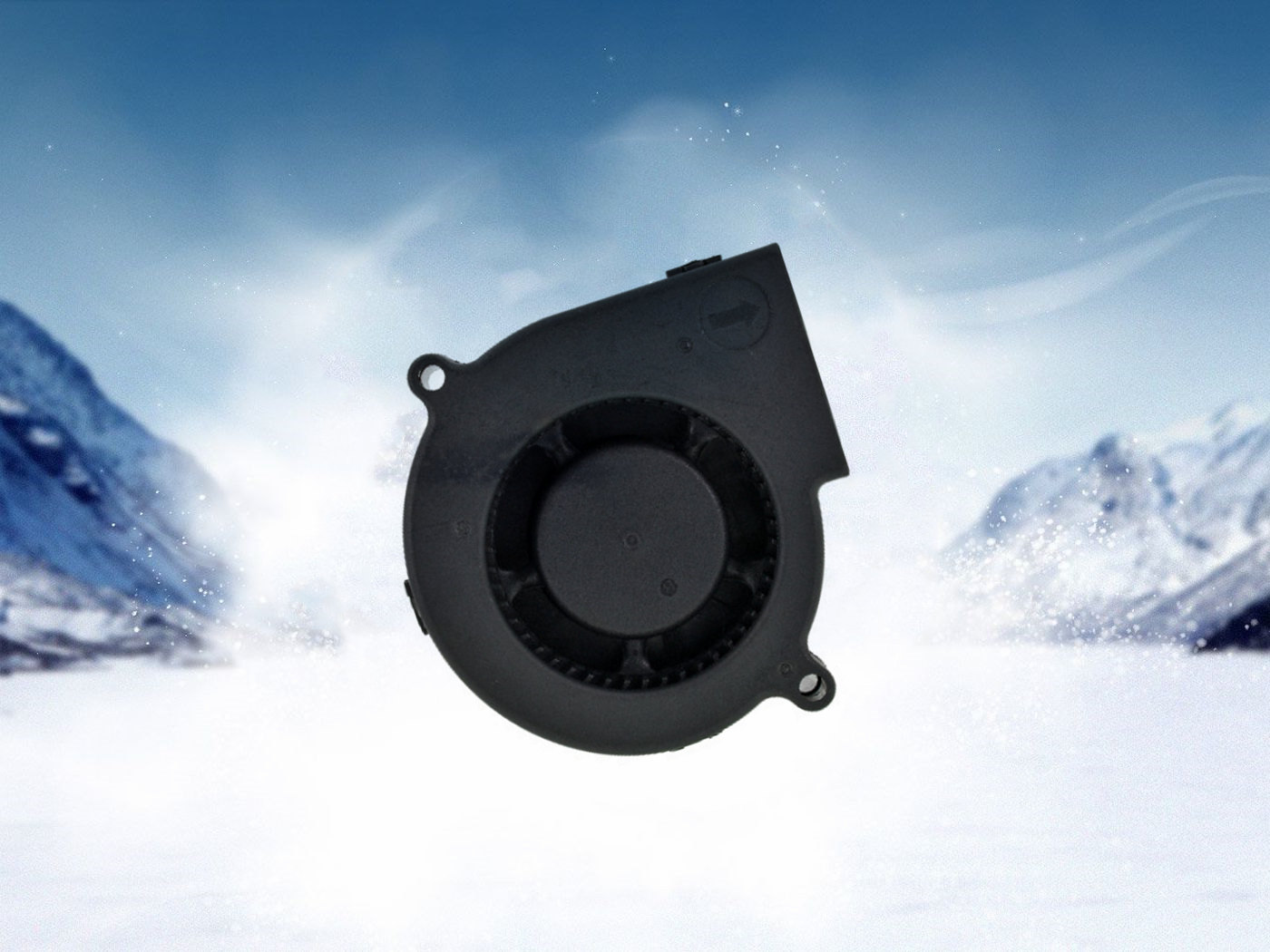

AC cooling fan is the major aspects of different varieties of industrial products, including electrical machinery and electronic digital products which all demands cooling fan as the major device for energy managing. By developing the environment flow, cooling fan provides cool air to decrease the temperatures of your industrial equipment, also, will help the industrial electrical or electronic digital projects to hold our prime effectiveness as well as its performance is definitely not minimized due to the heat produced.

As the part of the electronic digital components, AC cooling fans are widely developed in the home appliance or different varieties of industrial electronic digital machinery. It is because AC coolinf fan offers stable air movement consistently, which assists to stable the machinery performance, hence the machinery is definitely not from operate due to the overheat.

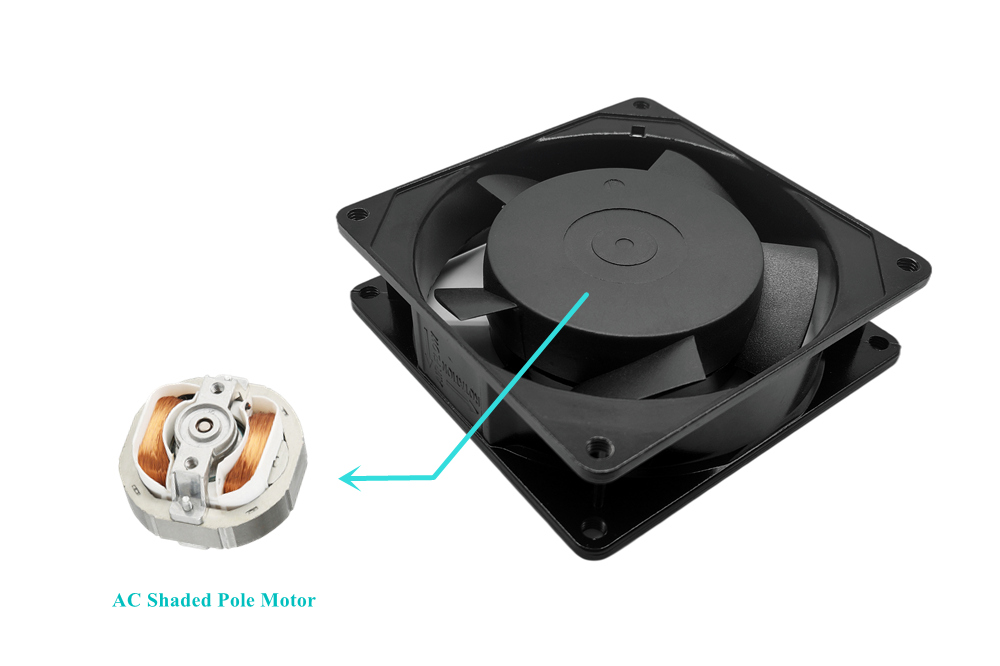

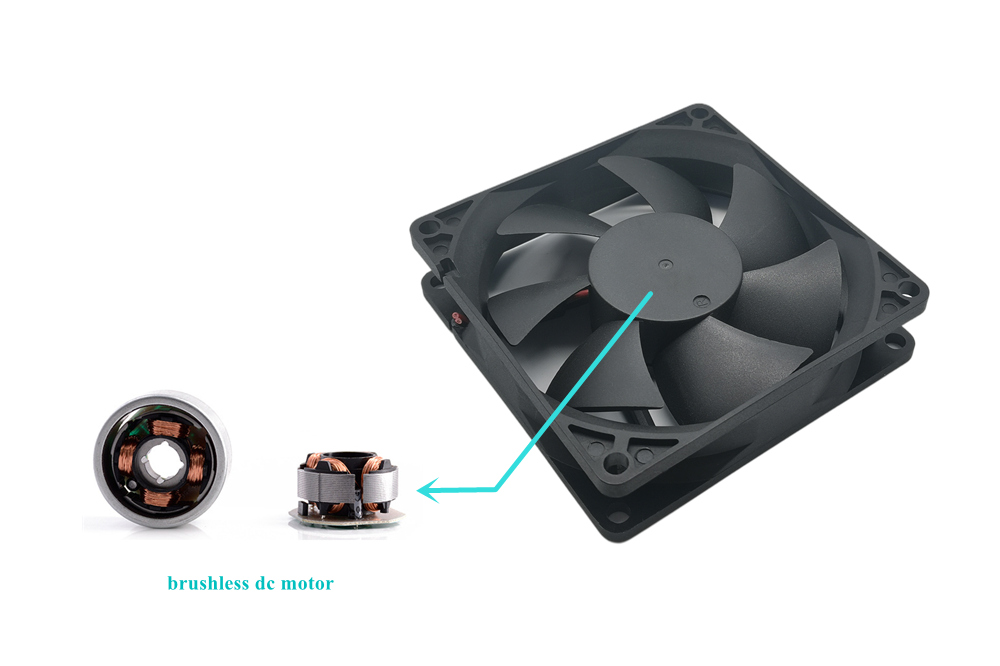

AC cooling fan works with AC power, and by operating of your impellers to generateair flow to decrease the temperatures of your machinery, which will help prevent the machinery from overheat. The many between AC fan and DC fan is – AC cooling fan air flow is stable and consistently, that may typical the machinery temperatures. Also, by changing the fan speed to meet the objective of energy managing.

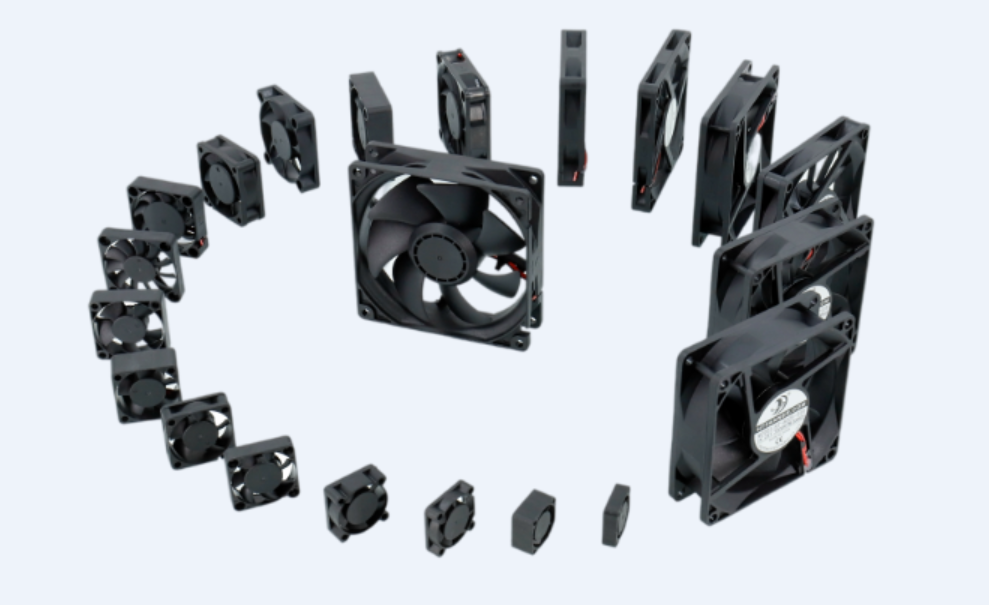

AC coolinf fan could be categorized in 2 major models, depending on its design –

AC axial fans – the air flow it creates is vertical with the fan impeller, the air in and out is in the same direction. AC axial fans’ main advantages are – big air flow, easy assembly, high efficiency, and high speed. With multiple product selection with different air flow and speed, it allows the users to choose the axial fans meets their requirements most. External rotor axial fans provides stronger air flow and higher speed, and with metal impeller design, it fits better for customers who need to use the fans in a rugged circumstance.

AC cross-flow fan the air-in direction is horizontal with air-out. The design of impeller and air-out area is narrow, which fits most to install on the flat machines, like elevators, air conditioners,electronic equipment and so on.

If you need to know more about Chungfo AC fan,please don’t hesitate to contact with us.