In small household appliances such as refrigerators, freezers and printers, heat accumulation is often one of the key factors affecting performance and lifespan. A highly efficient and reliable DC blower can not only solve the heat dissipation problem, but also effectively reduce noise and energy consumption. For R&D personnel or purchasing decision-makers, mastering how to calculate the basic parameters of a blower is the first step in choosing a suitable model.

1.Why are DC blowers the first choice for heat dissipation of small household appliances?

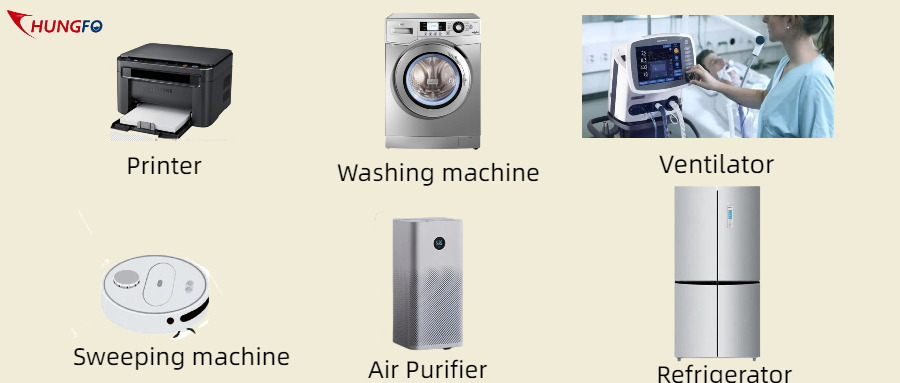

Compared with AC fans, DC blowers have the advantages of small size, low energy consumption, fast response, and low noise, and are very suitable for:

(1). Air circulation in the refrigerator refrigeration area

(2). Heat dissipation of refrigerator refrigeration components

(3). Heat dissipation of thermal components inside printers

(4). Heat dissipation of electronic modules such as smart toilets and water dispensers

Small appliance manufacturers usually give priority to consulting dc blower supplier during the design stage to obtain model parameters suitable for different voltage and wind pressure requirements.

2.Calculate the key parameters of DC blower

Before determining the fan model, it is recommended to perform the following calculations:

Before determining the fan model, it is recommended to perform the following calculations:

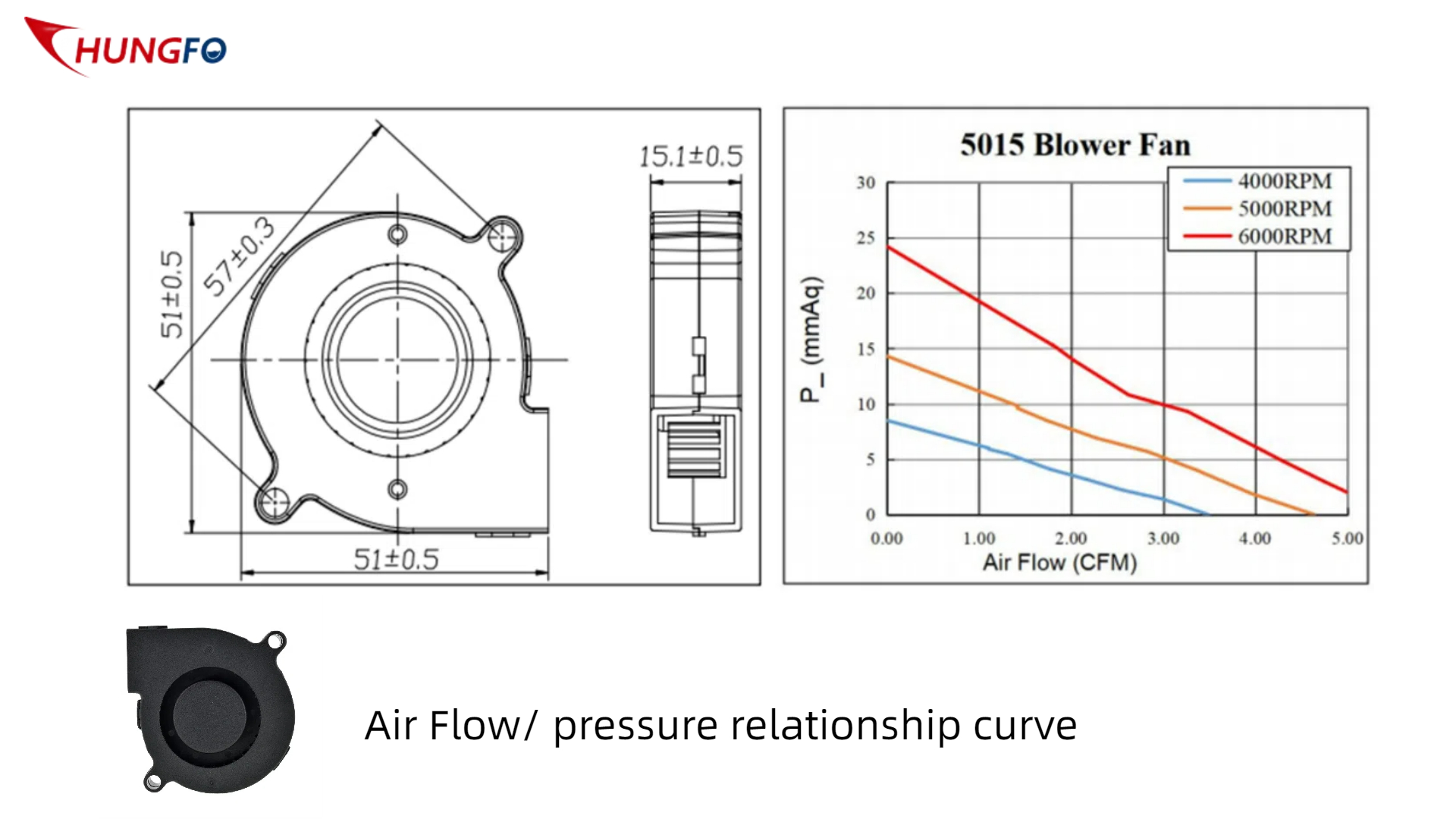

(1). Air volume (CFM or m³/min)

The air volume reflects the amount of air flowing per unit time. Taking the printer as an example, the internal heat dissipation space is small but the airtightness is high, so a model with high air pressure and moderate air volume should be selected.

Simple estimation formula:

Air volume ≈ heat source power (W) × heat dissipation coefficient (usually 0.06 ~ 0.1)

Example: If the heat source power is 60W, an air volume of about 3.6 ~ 6 CFM is required.

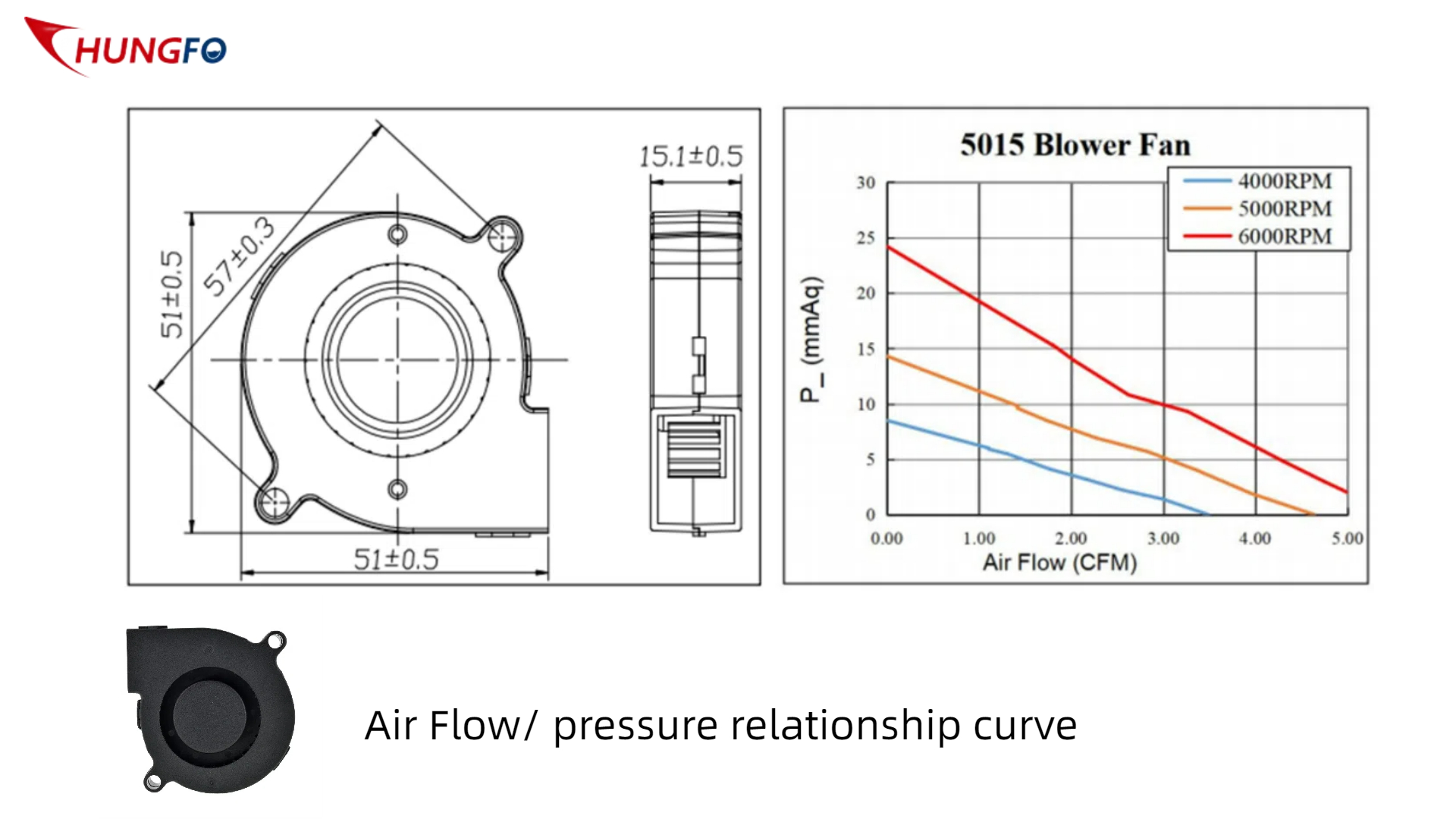

(2). Static pressure (mmH₂O or Pa)

Especially in freezers and refrigerators, if it is necessary to penetrate partitions or filters, high static pressure blowers are more suitable. You can communicate with the wholesale 24v DC blower factory about the specific ventilation resistance value and match the appropriate fan.

(3). Input power calculation

Power = voltage × current. For example, a 12V blower with a current of 0.3A has a power of:

12 × 0.3 = 3.6W

This value helps to evaluate the overall system energy consumption and power compatibility.

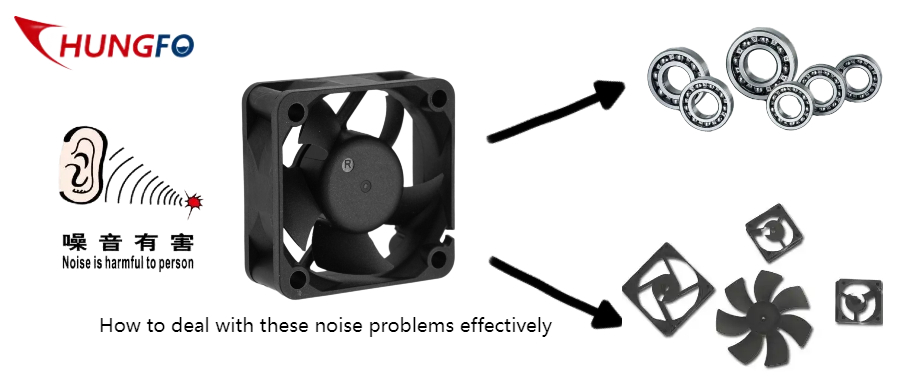

(4). Noise level (dBA)

Household appliances have high requirements for quietness. It is recommended to choose a blower model with ≤30dBA. You can ask for a test report or measured value from the wholesale 12v blower manufacturer.

3、How to choose a reliable blower manufacturer?

(1). Do you have experience in the small appliance industry?

(2). Do you provide real test data and 3D drawings?

(3). Do you support proofing and fast delivery?

(4). Can you provide stable supply and support after-sales technical response?

Choosing a wholesale 12v blower fan manufacturer with R&D capabilities like our Chungfo Electronic Technology Co., Ltd. can not only ensure smooth technical docking, but also reduce problems during small-batch trial production and large-scale production. At the same time, most professional wholesale 24v dc blower fan factory will also provide voltage customization, wire customization and outlet direction optimization to facilitate customers' rapid integration.

For small household appliances with compact structures and diverse working environments such as refrigerators, freezers, and printers, the stability of the cooling system is crucial. Mastering the basic calculation methods of DC blower air volume, static pressure, power, etc. will help to make more accurate preliminary selection and testing.

If you are looking for a small blower solution for household appliances, please contact us. We have many years of experience in cooperation with Midea, as well as with large companies such as Chigo, Skyworth, Hitachi, LG, and Icon. We are not only a DC blower supplier, but also have rich customer service experience, and are committed to providing you with more stable, quieter, and more energy-efficient blower products.