Advantages and disadvantages of cooling fan bearings in the home appliance industry

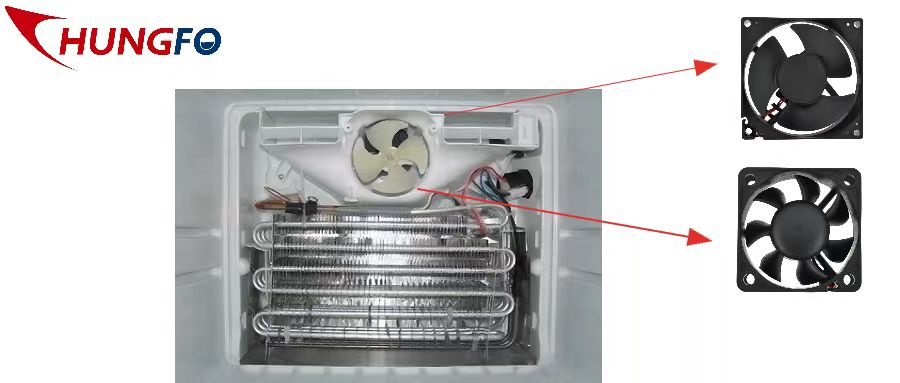

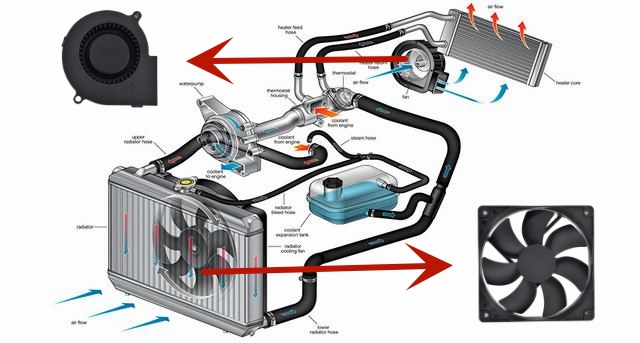

Many home appliances need heat dissipation during use, so cooling fans are usually installed to achieve the purpose of heat dissipation. In the process of using home appliance industry cooling fan, fan bearings play a decisive role in the service life, noise and reliability of cooling fans. According to the fan bearing, it can be divided into oil bearing exhaust fan and ball bearing exhaust fan. The price of oil bearing fans is relatively low, but oil bearings are dragging friction. In long-term use, the lubricating oil is used faster, so the bearings are more likely to be broken, and there will be loud noises in the middle and late stages. The ball bearing belongs to the rolling friction, which has the characteristics of high efficiency, low heat generation, small friction coefficient and small damage. Therefore, the service life is generally longer. With the development of the home appliance industry, oil bearing fans have been unable to meet its heat dissipation requirements, so ball bearing fans have gradually become the mainstream of home appliance industry cooling fan today.

During the production and processing of cooling fan bearings, the key stages of quality include the production and manufacture of bearing steel balls, the use of refined oil, cleaning during processing, the application of aerospace-grade stainless steel plates, and high-precision assembly lines. Since the bearing has a great influence on the cooling fan, it is particularly important to control the quality of the bearing.

In addition, high-quality bearings and fake and inferior bearings do not look very different in appearance, but their technological content cannot be compared. The significant technical differences in the production process of the two bearings can be reflected through the analysis and comparison of the bearing preload characteristics. Preloading refers to the entire process of fixing the balls into the bearing sleeve, which stipulates that the balls are inseparable from the surface of the bearing sleeve, and there is no play. Whereas in inferior bearing manufacture, the left and right bearing sleeves are directly aligned before preloading. There is no doubt that there will be some deviation between the steel ball specification and the bearing sleeve specification, so after preloading the bracket bearing, there will always be 5-10 gaps between the ball and the bearing sleeve, which greatly increases the degree of embrittlement damage, Reduced bearing life. In the same overall process, when high-quality bearings are produced and manufactured, the relative spacing between the left and right bearing sleeves during preloading is 5 microns, so that the bearing sleeves will firmly lock the balls after being stressed, thereby reducing the clearance to zero. In this way, during the operation of the fan, the balls are not easy to vibrate, thereby minimizing the damage and ensuring the stable and long-term high-speed operation of the cooling fan.

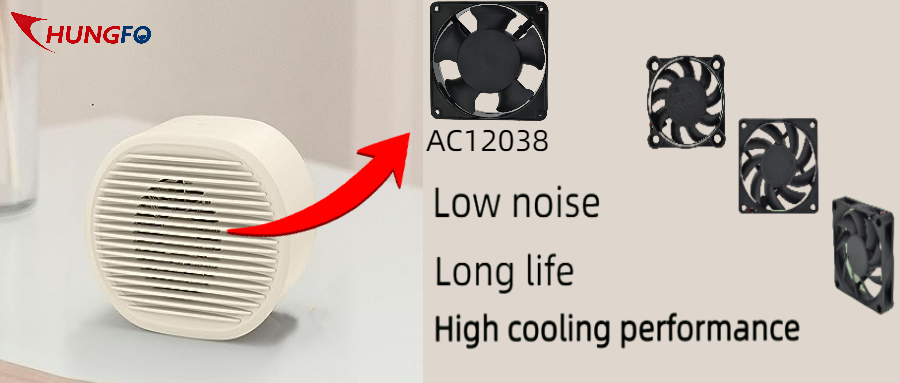

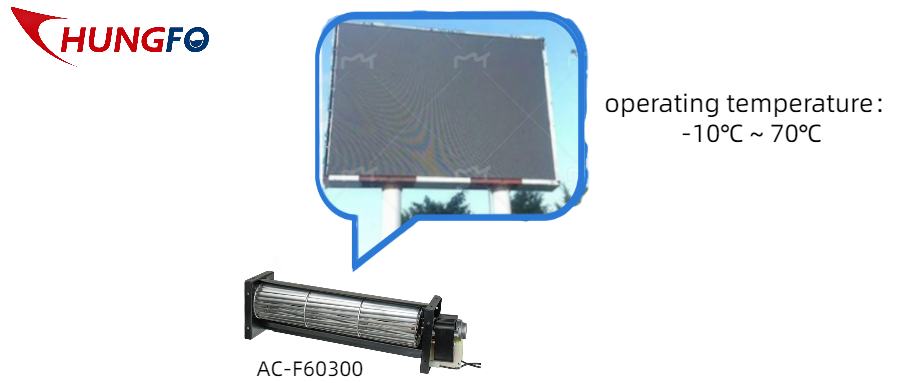

Guangdong Chungfo Electronic Technology Co., Ltd. is a professional cooling fan manufacturer dedicated to the equipment cooling needs of various industries. We can provide professional customization of cooling fans according to customer needs. If you have needs in this area, please feel free to contact us.