Principle and application of PWM speed regulating cooling fan

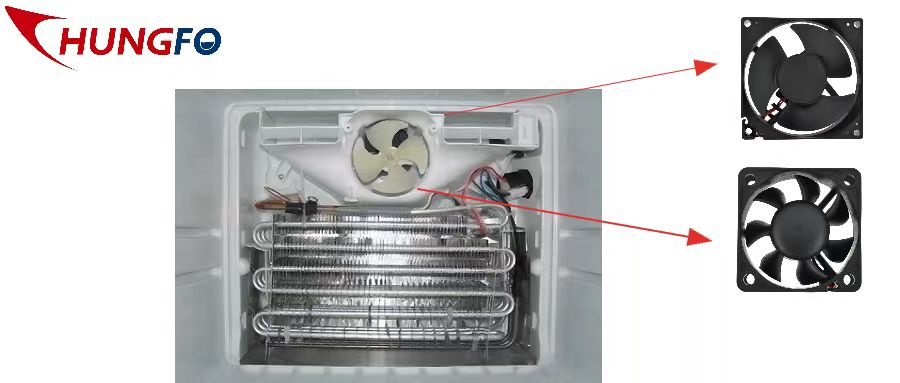

Today, with the rapid development of electronic products, cooling fans are applied to almost all industries, such as medical equipment, intelligent household appliances, sports equipment, power supply equipment, communication industry, security monitoring, military equipment, automobile industry, automation industry, etc. in these industries, general cooling fans are far from meeting the needs of various equipment. Therefore, fans with PWM speed regulation function have become the first choice for intelligent devices, For example, humidifiers, massage chairs and frequency converters all need PWM speed regulating cooling fans.

Intelligent devices require different cooling effects of cooling fans in different time periods and working hours with different degrees of load, which can effectively reduce energy consumption, extend the service life of the device, and enable the device to reach the best state in any operating state. In addition, when the device is overloaded, it will generate more heat than usual, it can also send a signal to the fan to quickly remove heat in a short time, To reduce the damage to the equipment caused by the high internal temperature of the equipment, which can not be achieved by the cooling fan without the PWM speed regulation function, so how does the cooling fan use the PWM function to regulate the speed?

1. The speed of the fan is adjusted through the control circuit, which is controlled by the pulse width modulation signal. There are four lines, and the standard fan has only two positive and negative lines. It can use the frequency and high and low voltage levels to control the speed of the cooling fan, and change the duty cycle through the PWM controller, so as to achieve the purpose of controlling the speed of the fan.

2. The PWM fan can set the most appropriate speed by detecting the ambient temperature through the temperature sensor, which can reduce the noise of the fan. The fan consumes less power when running at low speed, which can prolong the battery life, reduce the noise emitted by the fan, and increase the service life of the fan.

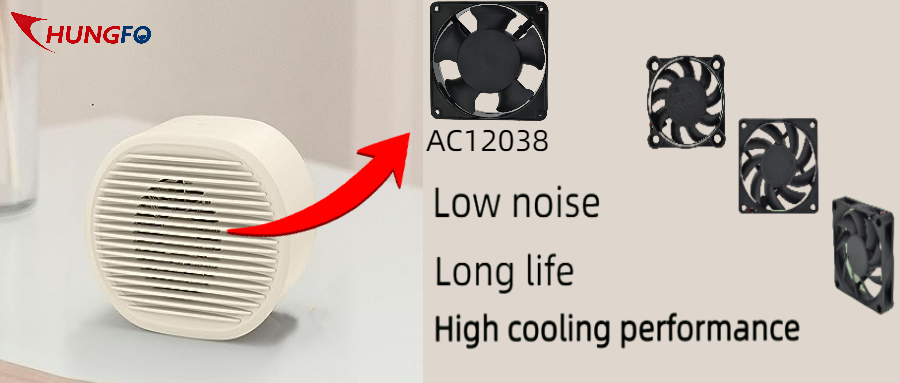

Guangdong Chungfo is a manufacturer specialized in R & D and production of cooling fans. Our fans support PWM speed regulation function and can also be customized according to different equipment working environment!