If the positive and negative poles are reversed, will the cooling fan burn out?

DC cooling fan has two positive and negative power lines. When installing the cooling fan, if the positive and negative lines are connected reversely by wrong operation, will the cooling fan burn out?

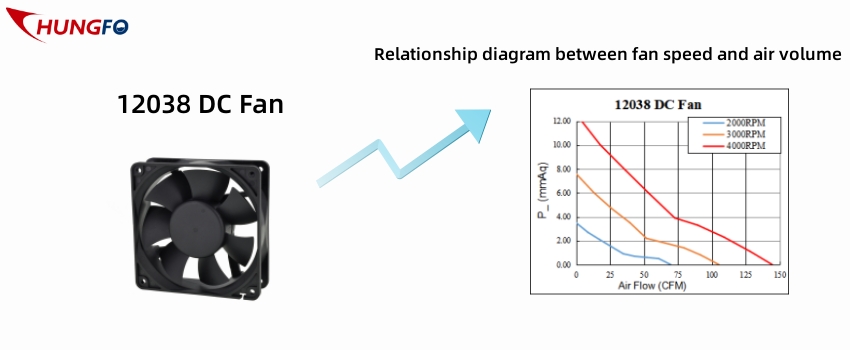

Whether the axial cooling fan is burnt out or not is mainly related to the IC Design of the cooling fan. In general, the drive IC with double wire winding method has internal protection design. If the positive and negative power lines are connected reversely, it will show the phenomenon of short circuit. At this time, the current of the cooling fan will be much higher than that under normal conditions. The motor current is large and its temperature rise is high. When the temperature reaches a certain degree, the driving IC will be damaged due to overheating and the cooling fan will be burned out.

Some of the single winding drive IC has no internal polarity protection. If the motor stator PCB is not designed with polarity protection, it may burn out the IC instantly when connected.

In order to prevent the ventilation cooling fan from burning out due to positive and negative polarity connection, a diode is added on the PCB of the cooling fan to design polarity protection, that is, when the polarity of the cooling fan is connected reversely, the current is zero, showing no power supply, so it can protect the cooling fan from burning out.