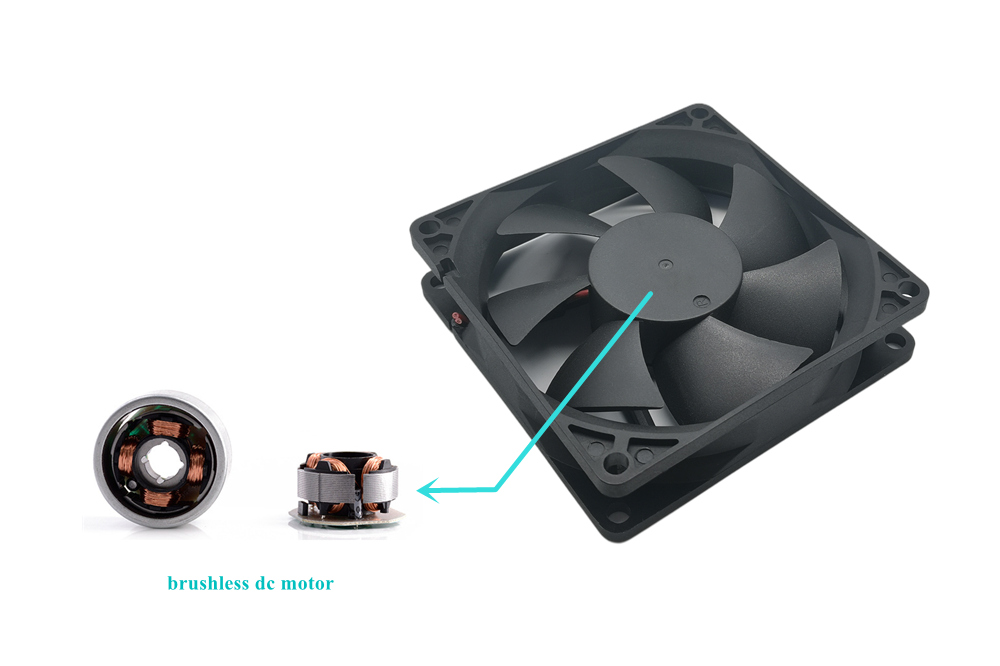

Cooling Fan - Brushless DC Motor

Motors that power ventilation cooling fans are usually divided into brushless motors or induction motors.

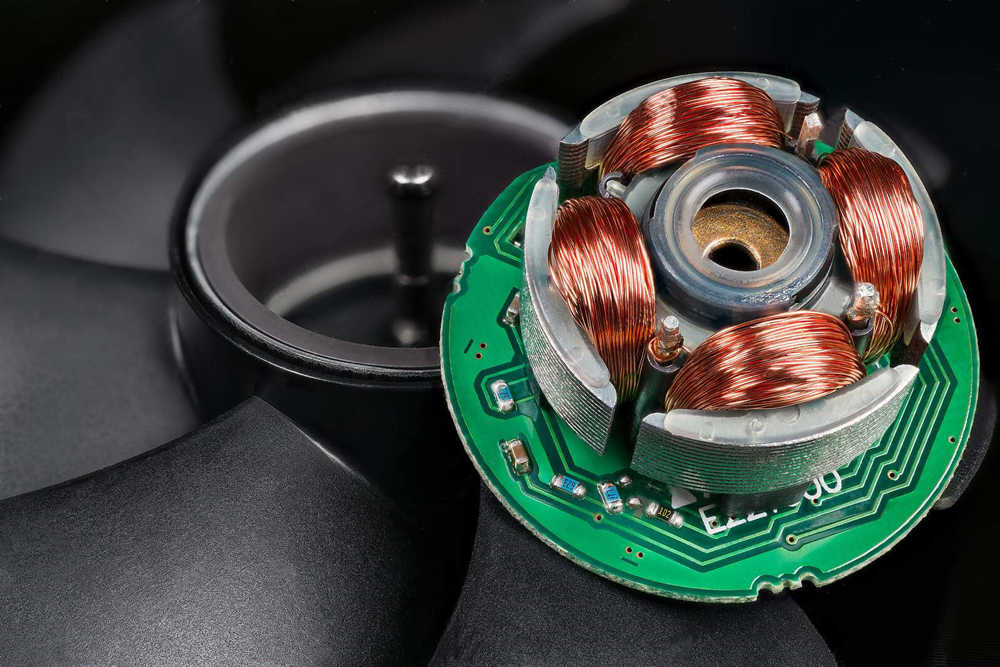

Brushless motors are sometimes called electronically commutated motors. Commutation refers to the act of switching the electrical connection from one motor winding to the next one. Motor windings in the DC cooling fan motor is generally located in the stator or stationary portion of the motor. Then the rotor contains a magnet with alternating poles. (DC motor with the magnets in the rotor are sometimes called outrunner. There are other possible configurations but they are not as widely used as outrunners.)

The brushless DC fan motor uses an electronic controller to sequentially energize the stator windings, turning them into electromagnets, in a sequence that turns the rotor. First, one set of coils (that is, a coil and the coil located 180º away from it) would be energized to become electromagnets. This causes the opposite poles of the rotor and stator to be attracted to each other. As the rotor nears the energized coil, the next coil is energized and the coil nearest the rotor pole is switched off. As the rotor rotates near the next coil on the stator, the coil nearest the rotor pole is switched off. This sequence repeats as the rotor runs. The point to note is that there is always one set of coils pulling the rotor, causing it to rotate.

In fact, the set of coils behind the set pulling on the rotor is energized in a way that pushes on the rotor rather than pulls it. So there is a combined effect of pulling and pushing on the rotor which gives this motor high efficiency. The combined effect is that most of the coils in the stator act on the rotor nearly all the time.

One aspect of brushless motor operation is the necessity of knowing the position of the magnetic poles in the rotor. In order to fire the right stator coils at the right time, the controller must sense the position of the rotor. The controller reads the rotor position sensor to decide what coils to energize.

The usual way to sense the rotor position is with a Hall Effect sensor. It’s also possible to measure the back-EMF in the undriven coils to infer the rotor position, thus eliminating the need for separate Hall effect sensors, but that scheme is a bit more complicated. The efficiency of brushless motor is usually 85% to 90%, mainly because most of the energy entering the coil actually drives the rotor.