What are the anti-corrosion measures for industrial cooling fans?

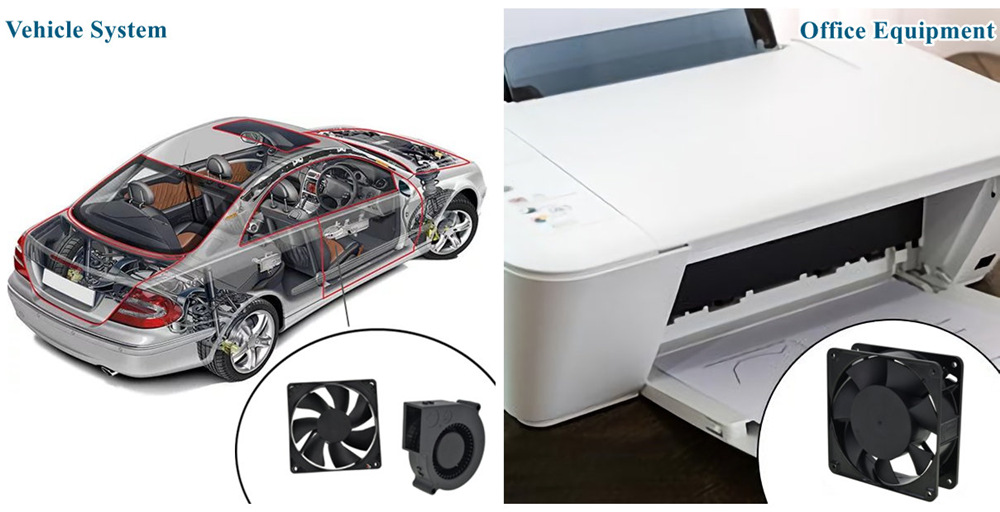

The production of industrial equipment is inseparable from the accessories industrial cooling fan. The main function of the fan is to dissipate heat, cool and remove dust for various sizes of equipment. The general production environment of industrial equipment is relatively harsh. In order not to shorten the service life of the industrial cooling fan, some treatment will be done for the fan. The following are some of the more common anti-corrosion measures for industrial cooling fans.

Appearance treatment of industrial cooling fans: The surface protection treatment of cooling fans usually adopts galvanizing, chrome plating, chemical plating and other methods. These methods are valid in many environments, but for rotating parts, you must choose carefully. Because the substrate and the coating are two kinds of materials, their linear expansion coefficients are different, which will produce different deformations in the elastic deformation of the rotating parts, which will produce a large number of micro-cracks and accelerate the formation of corrosion. Therefore, the appropriate process must be selected according to the actual use environment.

Design of industrial cooling fan: The design of cooling fan is the performance of its core technology, and also affects the service life of cooling fan. In the structural design of cooling fans, the design defects most prone to accelerated corrosion are stress concentration tendencies and interstitial environments. Sometimes the corrosion rate in the metal immersion solution is small, but the formation of gaps can cause severe crevice corrosion due to changes in the chemical and electrochemical states of the internal solution, which requires careful design.

Materials of industrial cooling fans: Different cooling fans use different materials and have different anti-corrosion effects. After selecting the cooling fan model, the strength of the parts is determined from the base surface according to the corrosion resistance of different materials in different environments, the main application environment, working strength and other factors.

Guangdong Chungfo Electronic Technology Co., Ltd. focuses on the cooling needs of equipment in various industries. We are a cooling fan manufacturer specializing in R&D and supply of DC cooling fans, AC cooling fans and DC blower fans, etc. The product quality is excellent, the cooling fan gauge is complete, and the professional customization of cooling fans can be provided according to customer needs.